When a customer walked into Merle Miller's machine shop in Odebolt, Iowa, complaining about the difficulty of keeping his pull-type sprayer on the row on hillsides, Miller decided to try to find a way to solve the problem. The result was a new hydraulic-controlled drawbar that works so well he put it on the market.

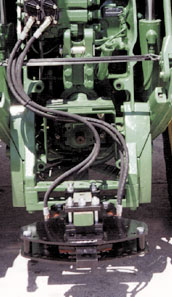

The new-style drawbar is fitted with two short cylinders that move the hitch 9 in. to either side. The drawbar simply attaches to the underside of any drawbar with five heavy bolts. It can be removed when it's not needed.

When pulling equipment on a slope, you simply shift the hitch to the upside to compensate for downward drift.

The hitch is built from heavy 3/4-in. plate steel. The drawbar is made of 1 1/4-in. plate. Miller is working on an even heavier unit for pulling extra-wide equipment behind big 4-WD's.

What's more, Miller has developed an automated hitch system that automatically shifts the hitch from side to side by reading the level of the slope. "It's the first automated guidance system for pull-type equipment," he says. A level switch mounts in the cab. It controls an electro-hydraulic valve mounted on the hitch that shifts the drawbar back and forth. A light bar in the cab tells the operator where the hitch is at any given time. Miller has a prototype in the field and plans to complete testing this year and have units on the market early in 2001.