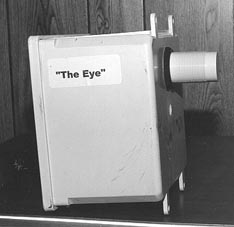

As a farmer and part-time electrical contractor, Mike Perry, Henderson, Neb., found over the years that mechanical sensing switches used in grain drying and conveying systems often weren't reliable. Dust and variations in grain moisture content often caused them to fail. To solve the problem he came up with his own "touchless sensor" that can sense both metallic and non-metallic objects with-out actually touching the object it senses. "The Eye", as Perry calls it, uses a plastic capacitive proximity switch, mounted in-side a pvc enclosure, to sense objects up to 1/2 in. away. The switch senses the capacitance of air around it and is activated whenever an object gets in its "zone". The switch is used to control relays that in turn control other loads such as auger motors or burners on grain dryers. The sensor is designed to be hooked up to a small relay so that two circuits may be controlled if desired. A bypass switch is used to switch between manual and automatic modes of operation. "The key is that it doesn't have to be physically touched in order to work. It'll take the abuse of dust and dirt," says Perry. "Because it's a 'touchless' switch it doesn't have any moving parts outside the control box that could cause the switch to 'hang up' and leave equipment running when it should have been shut down. Both the sensor and control box are made from plastic so corrosion won't ever be a problem. Best of all it'll save time and money because you won't have to babysit your grain dryer in the middle of the night. When the bin gets empty it'll automatically shut off augers, burners, grain conveyors, etc., until you can get there. By mounting it in the top ring of a storage bin you can use it to without actually touching them. automatically shut off or turn on roof augers when the bin gets full. Prevents spills from over-filling. "The sensor can also be used on a grain pit to automatically shut down the auger and/ or elevator leg when the pit is empty. You can use it with a time delay to let the elevator leg and/or auger continue to run until they have time to empty out. You just dump the load and go. "The sensor can also be used to shut off and/or turn on livestock feed conveying systems when feeders are full or when bulk bins are empty." Six different time delay models are available, ranging up to 30 minutes.

1-800-834-9665

"Touchless" Sensor For Grain Dryers, Livestock Feeding Systems

FARM SHOW Magazine » "Touchless" Sensor For Grain Dryers, Livestock Feeding Systems

"Touchless" Sensor For Grain Dryers, Livestock Feeding Systems