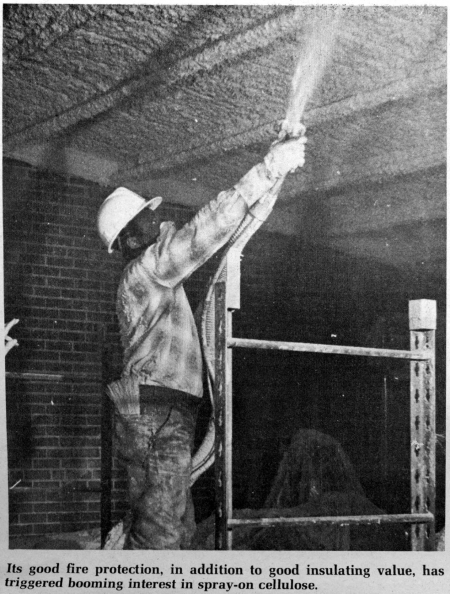

Its excellent resistance to fire and condensation has triggered nationwide interest in this spray-on cellulose wood fiber insulation for new or existing farm buildings.

Technically, it isn't completely fireproof -- in that it will burn under extremely intense heat. But, with a flame speed of 25 or less, it's classified as a Class A, non-combustible material. It won't burn under a hot blow torch flame and, unlike some other types of insulation, doesn't melt down or produce toxic fumes when exposed to intense heat. Because of its excellent fire resistance, it's catching on fast as a protective coating sprayed over highly combustible foam insulation's to reduce the danger of fire.

Cellulose wood fiber has been around for years as a loose-fill type of insulation. Now, thanks to new equipment and a new liquid adhesive, it's available as a spray-on insulation that adheres to metal, wood, concrete, glass and most other surfaces.

"Business is booming," reports Dale Pollock, president of Diversified Insulation, headquartered at Hamel, Minn. In the past two years, his firm has opened branch manufacturing plants in Kansas, Iowa and North Dakota to meet growing demand for cellulose fiber insulation. The firm sells loose-fill insulation and spray-on insulation under the Shelter Spray label.

Another major manufacturer is Thermo Products Co., headquartered at Clinton, Texas. It manufactures spray-on cellulose insulation under the trade name of ThermoCon, which is sold through regional Thermo Product sales offices in Tulsa, Okla., and Memphis, Tenn.

"Farmer interest in ThermoCon has been tremendous," reports Leon Sitton, president of the Memphis office. "Some are having it sprayed over foam insulation for fire protection. Others are using it primarily to solve condensation and humidity problems in existing buildings."

"From 44 to 66% of the insulation value of the vinyl-faced blanket insulation is lost when the blankets are stretched between purlins and girts," Sitton points out. "When the blankets are stretched from the top of one purlin to the top of the next, the true R value is only achieved in the center between the two. Spray-on ThermoCon, on the other hand, completely covers purlins and girts, conforming to their exact shape and width with no heat leaks or breaks. You get 100% insulation of the sides for maximum efficiency."

A relatively new wrinkle in insulation for farm buildings is to erect false ceilings, with lower-cost loose-fill insulation poured 8 to 10 in. deep on top of the false ceiling. Walls below the false ceiling are sprayed with spray-on cellulose insulation which, because of its good fire protection, needs no additional paneling or other protective cover -- unless, of course, it's a livestock building. In this case, the lower area exposed to animal contact would have to be protected with paneling.

In setting up new dealerships, Pollock insists, as part of the contract, that the new dealer and his equipment operators attend a training session, "We also insist that one of our men help with the first job or two to check out equipment, operators, procedures and so forth."

Spray-on insulation can be applied to older metal or wood surfaces, provided the surface is clean and free of grease and rust. If old metal is rusty, it should first be sandblasted.

Another limitation is that the insulation can't be sprayed on in cold weather. "We like to see outside temperatures above 50 degrees F. both day and night on the day of application, and for about a week following application," says Pollock.

Spray-on cellulose has excellent tolerance for condensation and humidity. "It's not a cure-all for moisture and condensation problems," Pollock emphasizes. "But, when combined with adequate ventilation, it goes a long ways toward solving common condensation and humidity problems if normal relative humidity of the building doesn't exceed 60%."

In most cases, farmers elect to have buildings sprayed with an off-white or tan colored insulation. It's also available in pure white, and it can be tinted to whatever color you choose.