"It's the first system specifically designed to stack dry-chopped hay or roughages in the field as the crop is harvested," says Howard Hanson, developer of the Hanson Dry Chop System.

Hanson notes that, "five years ago, very few feedlots were buying chopped hay. Today, many are buying only chopped hay. This is a trend which can only continue because chopped hay is more efficient and feedlot operators avoid the cost of tub-grinding hay."

Here, according to Hanson, is how the system has stacked up in research trials: "Field tests conducted at Lamed, Kan., by Kansas State University researchers on July 22 last year, showed the Hanson Stacker to be 16.7% more efficient than the Hesston under field conditions prevailing that day, and 2.4% more efficient than the New Holland self-propelled baler. The reason we save more hay than loose starkers is that we have no screen in our machine to blow the fines through. And, by adjusting the wind on your chopper, you can use just enough air to fill the stacker with minimal loss. It takes a lot less wind to move chopped hay than loose hay. With hay presently selling for more money per pound than milo, this is important."

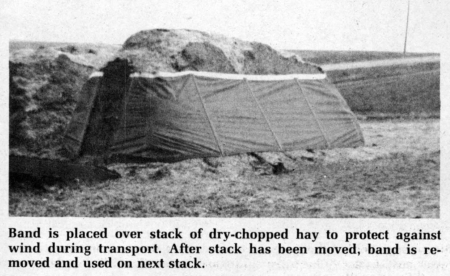

Model 113 stacker makes a dense, 2-ton stack without the expense of twine or wire. It tows behind your chopper, thus eliminating costly winter regrinding of the hay. Stacks can be retrieved with a Hanson built retriever, or a front-end tractor loader. The hydraulically operated stacker uses no chains or sprockets.

For larger or custom operators, Hanson has introduced a new model 313 stacker which makes 3 to 5-ton dry-chop stacks.