A "groovey" new guidance system that's unbelievably simple and reasonably priced will automatically steer your tractor with precision accuracy for planting, drilling, cultivating or spraying while you sit back and relax -- at least until you get to the end of the field and have to grab the wheel to turn around.

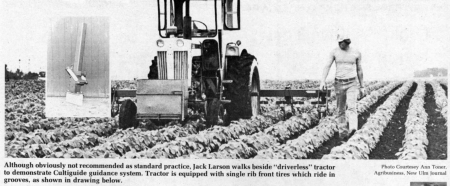

"Interest has been tremendous," says Minnesota farmer John Clair Larson, of Clements, who teamed up with his son Jack to invent and manufacture the new guidance system called the Cultiguide. "It not only steers the tractor but keeps the cultivator shovels the exact same distance from the row at all times for maximum weed control and minimum crop damage."

Here's how it works:

A pair of identical chisel-type attachments are mounted on the rear of the planter. They're mounted the exact distance apart as the front wheels of the tractor to be used for cultivating. During planting, these "groove-makers" each dig a trench 4 to 5 in. deep.

For cultivating, the front wheels of the tractor are equipped with pointed single-rib tires which ride in the grooves to provide automatic steering. As you cultivate, the rear mounted, groove-making attachments (taken off the planter) ride in the same pair of grooves. You pull the pins on the 3-pt. hitch, allowing the guides to keep the free-swinging cultivator a uniform distance from the plants at all times. The rear-mounted "groove-makers" also make a fresh pair of tracks to set the stage for the same precision accuracy on the next cultivation.

The complete "package" consists of two groove-making attachments, mounting brackets for both the planter and cultivator, and two single-rib front tires mounted on rims. In addition to all row-crop planters, the groove-making attachments can be mounted on Tye drills used for planting soybeans or other cultivated crops.

Two significant developments were being finalized as this issue of FARM SHOW went to press:

1. The Larson's were negotiating with Lindsay Brothers Co., headquartered in Minneapolis, Minn., to have their Cultiguide guidance system marketed throughout the Midwest. Sales to farmers in other areas of the U.S. will be handled through other distributors or factory-direct, according to the Larson's who have set up their own J & J Guide Systems manufacturing plant in Sanborn, Minn.

2. The Larsons have just introduced the Mark-N-Guide System. It's designed for precision planting, whereas the companion Cultiguide system is for precision cultivation. Individual markers for the right and left side of the planter (or drill) are equipped with two disks. They dig a pair of tracks which the tractor, equipped with single-rib front tires, follows to automatically steer itself with precision accuracy when planting.

Here's a closer look at the two guidance systems for planting and cultivating which can be used together or separately:

The Mark-N-Guide For Precision Planting

"This is a completely new kind of marker. There's nothing else on the market like it," says Merle Ophaug, vice president of merchandising for Lindsay.

"After we got it running last spring, we had 12 farmer friends over to see it work. They all wanted to buy one without even asking the price," Larson told FARM SHOW.

The new Mark-N-Guide is similar to the Cultiguide in that it runs two special disks alongside the planter (or drill) which are spaced to match the width of the front tractor wheels. The disks dig 2-in. grooves that hold the tractor's single-ribbed front tires on course to produce almost perfectly spaced rows between passes. The same single-ribbed front tractor tires used for the Cultiguide guidance system for cultivating, will work for the double-disk planter marking system.

The Larson's note that even with regular front tires on the tractor, the double-disk marker is a big improvement over conventional markers because the two grooves are much easier to follow than a single scratch running between the wheels.

"This marker is especially good for the farmer who doesn't have a matched planter and corn head," explains Jack Larson. "For example, he might have a 4-row planter and 6-row corn head, or an 8-row planter and a 6-row corn head. The 'guest rows' have to be straight or you'll lose a lot at harvest. Using the new doubledisk marker on our own corn planter last spring, we found less than 1-in. difference in width on those connecting rows," Jack points out.

How can grooves only 2 in. deep hold the tractor and planter in line with almost no manual steering?

"When the grooves or ditches are fresh, it doesn't take much to guide the tractor," answers Jack. "The tracks laid down by the disk markers aren't meant to stand up for cultivation. To get automatic steering for cultivating, you simply mount the Cultiguide groove-making units on the planter."

The frame of the new-style marker is made of 2-in. sq. steel tubing. The two cutting disks mounted on each left and right side marker are a special design. "We tried a tooth-type marker but that wouldn't leave a good enough mark. After several months, we finally perfected this disk pattern and it works great," Jack points out.

He and his father manufacture their new-style marker to fit Deere and International corn planters up to 8-row, and have put together a special unit that fits the Tye drill. Markers to fit other planters and regular grain drills are available on special order.

The Cultiguide For Precision Cultivation

"Most farmers can hardly believe what this guide will do until they see it work -- especially that you don't have to steer the tractor when you use it," explains Jack. "Last spring, we gave Cultiguides to a number of farmers in Illinois and Iowa to try before buying. So far, we haven't gotten a single one of them back. The device not only steers the tractor but holds it a uniform distance from the plants at all times to provide close-up cultivation at high speeds. It allows whoever drives the tractor to do a super job of cultivation by eliminating mental mistakes, such as getting too close and accidentally cutting plants out of the row. Another advantage is that you can let less experienced help do the cultivating while you do more important work."

He adds that sometimes you can't even see the guide tracks or grooves by the time you cultivate, but they're still there -- and the tractor rides them. "We tried the Cultiguide on hilly ground in Iowa this past summer and found that it holds the cultivator right on track without drift, although you may have to steer a little -- mostly because power steering units are pretty rigid," Jack explains. The solid steel shoe or shovel on each Cultiguide "groove-maker" is 1 in. wide, 10 in. long and 5 in. high. The front edge is beveled and, with hard surfacing, shovels have shown no wear after 1,500 acres of use, according to Jack.

The shaft of each Cultiguide "groove maker" is made of 3 by 3-in. steel tubing. A spring-loaded trip a third of the way up the shaft automatically resets itself if tripped after striking a rock or other obstruction. Individual units weigh about 56 lbs.

The Larson's manufacture mounting brackets to fit all Deere and International planters, and a standard bracket that fits all makes of rear mounted cultivators. "Install the brackets on your planter and cultivator and you're set," explains Jack. "The Cultiguide units slip in and out of these mounting brackets, making it easy to transfer a set from planter to cultivator."

Here, according to the Larson's, is a recap of key advantages which their packaged Cultiguide automatic guidance system provides:

--You scarcely have to do any steering of the tractor, except at the ends. You can cultivate at high speeds without tearing out or covering plants. You can sit back and relax while traveling down the rows, which cuts fatigue.

--With automatic steering, inexperienced help can handle cultivation as a routine job, freeing you for more important work.

--The Cultiguide's digging shovels will work in sticky or wet soils which, according to the Larson's, is sometimes a problem with other mechanical guidance devices commonly used by sugar beet growers.

--Because the groove-making shovels are long and deep, they hold the cultivator in place on hillsides to avoid side-drift.

--The Cultiguide grooves will not wash away, except under exceptionally heavy rains and flooding. The units can be set to any row width and used for any row crop. In addition to cultivating, they can also be used for spraying.