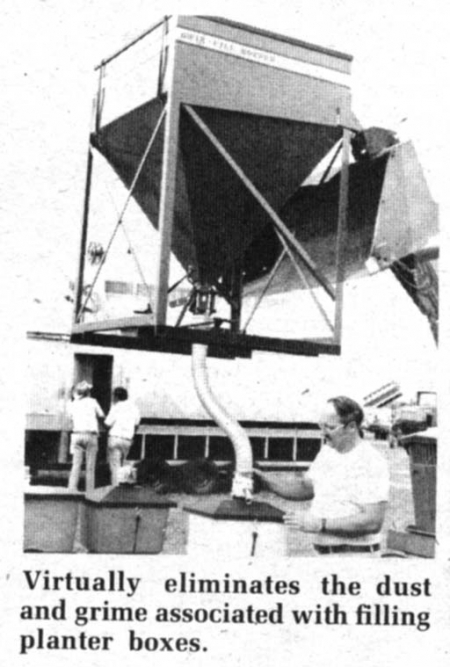

Filling planter insecticide boxes is one of the dustiest, most dangerous and wasteful jobs on the farm. To solve the problem, T-A-G Manufacturing in Valparaiso, Neb., has come up with a fill system designed for air-tight chemical filling that doubles as a seed hopper for filling seed boxes.

Partners Tom Trutna, Al Mittan and Gary Hellrich, built their first "Qwik-Fill" hopper system for a local farmer who was concerned not only about losing chemicals in the wind when filling boxes, but also about exposing himself to the dangerous chemicals as the dust blew around.

"We can virtually eliminate the dust and grime associated with planter box filling," says Tom Trutna. "The airtight hopper is connected by flexible hose with quick-connect couplers to the intakes on the special lids. The flow is controlled by a ball valve at the base of the hopper, delivering the flow directly into the boxes."

When full, the hopper holds about 28 cu. ft. of granular chemicals,which translates to about 1,000 lbs., or 20 bu. of seed. "The special airtight lids which are used for insecticide boxes to cut down on dust are not necessary on the planter seed boxes because there's less dust," explains Trutna.

The hoppers, which are painted in red or green, bolt quickly to the tractor loader bucket with a bracket that fits over the upper lip of the bucket. A safety bracket is also available which maintains a set height for the tractor loader and prevents it from falling while you're working beneath it.

The unit comes with a fill hose about 5 ft. long. Longer hose is available for filling more boxes at once.