Taking the 1st place prize at the 1982 Minnesota Inventors Congress was the Guard-Bender, developed by John Kapphahn of Elbow Lake, Minn.

"The Guard-Bender will pay for itself in no time at all," says Kapphahn. "With the price of guards, it's easy to recover the cost of the unit by fixing just three guards. And, unlike a hammer, you're less likely to bust the guard.

"It's simple to use on all types of sickle guards, except the real old single section mower guards. They're too big.

"Besides saving the guard," Kapphahn adds, "The Guard-Bender keeps guards straight, cutting down wear and tear on the sickle sections and cutter bar bearings."

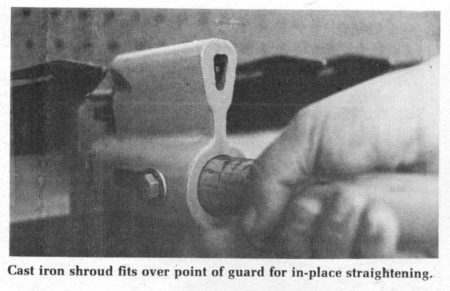

It consists of a 32-in. long, heavy duty, 8 ga., 1-in. dia. tubing, 1/4-in. thick, and a shroud that fits on top of the tubing fastened with a 3/8-in. bolt. The bolt loosens to allow adjustment for different sized guards. The shroud, made of 80,000 psi cast iron, has an opening that fits onto the guard.

To use, slide the shroud over the point of the guard and slide the tubing up until the notch at the end of the tubing catches on the base of the guard, right under the sickle. When it catches, you can bend the guard up, down, left or right without putting pressure on the sickle because the force is on the fulcrum on the bottom of the guard.