"Hand unplugging is eliminated with these nozzles," says John Vessels, inventor of a new "no-plug" spray nozzle that he has built and patented but that is not yet on the market.

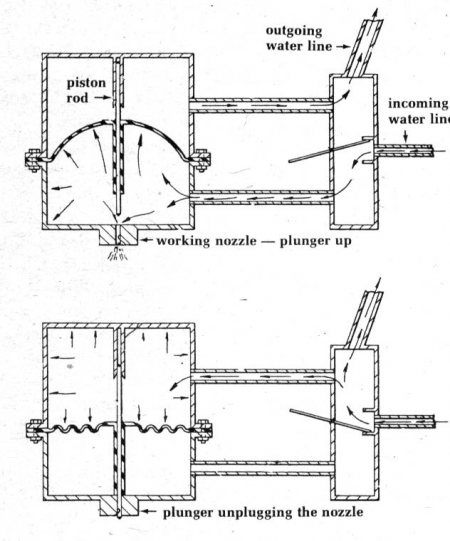

The nozzle, about 3 times the size of a conventional spray nozzle, consists of a stainless steel canister divided into two chambers, one above the other by a thin rubber diaphragm with a small piston rod in the center of it. There is a water intake into both the upper and lower chambers.

When the lower chamber is flooded with water, it simply exits via the nozzle opening located there. But, when the upper chamber floods, it forces the diaphragm downward and with it the punch, ramming it through the nozzle orifice and forcing out any debris that might have plugged the opening. Once clear, the sprayer is again reversed.

"I became concerned primarily because of the hazards of chemicals. The experts tell us they are safe but who knows what effect they may have 30 years from now. With this invention, you can clean them out from the tractor seat with no exposure whatsoever," says Vessels.

The only sprayer modification necessary with the new nozzle is installation of a two-way valve on the spray pump to reverse direction of liquid. The two-way valve also acts as a shut-off valve, pushing the punch into each nozzle orifice, plugging them during the row end turns so they won't drip.

Vessels has built a prototype nozzle and says that if he can't find a manufacturer interested in the idea, he has plans to produce the units himself.