"We bought a 10-in. diameter hydraulic cylinder and designed the rest of the machine around it," says Stuart McFadden, Canadian hay dealer who, along with Stephen French, designed and built what they believe is "the fastest portable bale squeezer ever made."

"The large cylinder is the secret. It provides the speed and power required to do an efficient job of compacting conventional hay bales. It makes 80 strokes an hour or one every 45 seconds," explains McFadden. "Because of its size, we can operate the cylinder with a lot of power (about 40,000 lbs.) but at a low psi (about 1,350), which means very little heat is generated. We never have to stop to let the machine, driven by a truck-mounted motor, cool off."

Operation

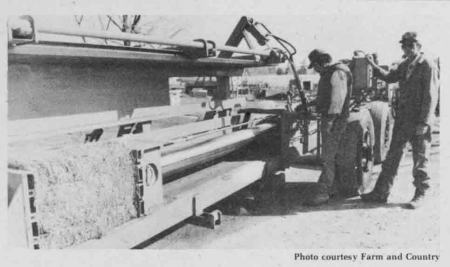

of the portable compactor (at a capacity of about 4.5 tons of compacted hay per

hr.) is a four man job -- one to feed in the bales, one to operate the compactor,

one to tie and one to remove compacted bales from the machine.

With 50-lb. conventional bales, two bales are squeezed into one 100 to 110-lb. bale measuring 16 by 19 by 29 in. Each compacted bale is tied manually with wire before being removed from the compactor.

McFadden notes that, normally, a truck can haul eight tons of conventional or standard-size bales. Compressing them allows the payload to be doubled -- without hurting quality of the hay, notes McFadden.

"We have blueprints and could have compacting machines custom built," reports McFadden.