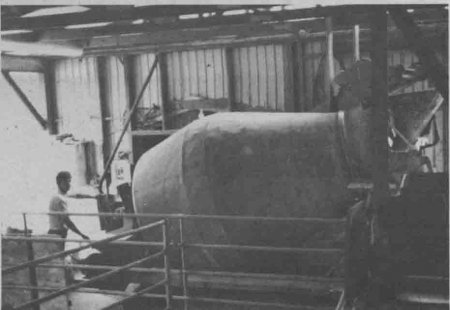

Steve Dornbierer, New Ringgold, Penn., turned a truck-mounted concrete mixer into a stationary feed mixer that will handle nearly 2 tons of corn silage.

"We bought the used mixer from a concrete 'redi-mix' company for 7 to 10 times less than a comparable-size stationary feed mixer would have cost. It's simply a barrel with auger flighting on the inside. When it runs forward, the feed inside runs in a pile at the front of the barrel, mixing thoroughly. To empty the barrel, we simply run it in reverse.

"The mixer has its own 6-cyl. gasoline motor. It had about a 5-in. build-up of concrete on the inside. We got this out with some effort by standing on the barrel and hitting the outside with a heavy sledge hammer. Then, by reversing the machine, the larger chunks broke up and almost all the concrete came out the back end.

"We've been using the mixer for over three years with very few problems. It's built heavy for concrete so we think it should last a long time with feed.

"One disadvantage of using a concrete mixer over 'store-bought' mixers is that material can't be added to the mixer with a front-end loader. We overcame this problem by running a conveyor into the mixer. We dump into a hopper at the end of the conveyor with a front-end loader."