"It's 10 times faster than a roller mill or tub grinder," says Clarence Sageman about a new high-speed corn "particulator", invented by his brother Frank, that grinds up corn and silage as fast as you can auger it through.

The design of the new "corn cracker" is simple. "It's got one rotating cylinder similar to a cylinder in a combine. The cylinder is spiked and turns inside a concave with about 1/8-in. clearance, cracking the kernel open but without creating a lot of fines," says Sageman.

The machine is ideal for processing silage as well as shelled corn because it breaks down the kernels within the silage, making them more nutritionally available to livestock.

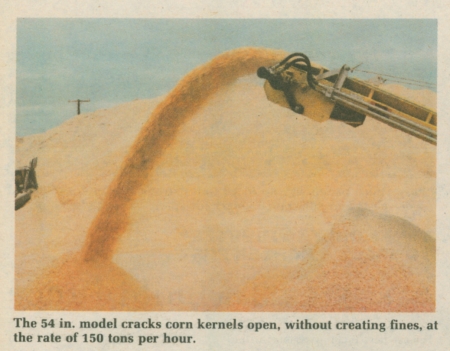

The particulator has a conveyor platform that carries grain up to drop it into the processing unit. A leveling auger halfway up the conveyor ensures an even flow. Material drops into the spiked cylinder where it's ground up at high speed and pushed out the end onto a conveyor or blower that carries it away. The 54-in. model, designed to process material going into bunk silos, processes 150 ton per hour. A smaller model, equipped with a 30-in. wide cylinder, is attached to a silo blower and processes material while filling silo.

"It has a high capacity but has a very low horsepower requirement. You can run even the biggest unit with the pto on a medium-sized tractor. It eliminates the problem of hammermills that require high horsepower, make too many fines, miss lots of kernels, have low capacity and lots of worn components. The cylinder and concaves in this unit show virtually no wear even after processing hundreds of tons of material," says Sageman.

Prototypes of the new machine have been operating on farms for three years. The Sagemans are looking for a manufacturer to take over production.