Air Seeder Built From Drills

✖  |

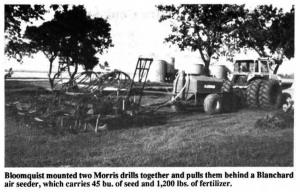

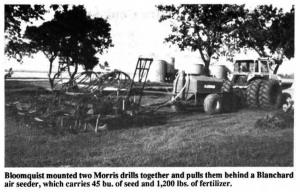

"It works as good as any air seeder on the market. I spent only $8,500 to build it," says Rudi Bloomquist, Starkweather, N. Dak., who converted two 11-ft. Morris hoe drills into a state-of-the-art air seeder by removing the seed boxes and metering drives and mounting a pair of seed-distributing manifolds on the drill frame. A two-compartment Blanchard air seeder caddy delivers seed and fertilizer to the manifolds which then distribute them through tubes to each hoe opener.

One compartment holds 45 bu. of seed and the other holds about 1,200 lbs. of fertilizer. Seed and fertilizer are blown by a pto-driven fan through hoses from the caddy to the manifolds on the trailing drill. Then 1-in. dia. plastic tubes deliver the mixture to pipe shanks that support the drill's hoe openers.

"I've used it for six years and have been pleased with its reliability and simplicity," says Bloomquist. "I've looked at several new air seeders and can't see that they have any advantages over mine. I paid $8,500 for the caddy and another $500 for an extra set of manifolds (which I can also use on a 33-ft. field cultivator to apply granular herbicides). Many of my neighbors paid $40,000 for their conventional 30-ft. air seeders.

"I used the two 11-ft. hoe drills together conventionally for five years. However, I wanted to switch to an air seeder delivery system because I wanted to apply dry fertilizer while seeding. The company offered an add-on, gravity-feed dry fertilizer system for the drill, but it would have cost $100 per foot or $2,200. I would have had to mount the gravity-feed fertilizer boxes 8 1/2 ft. off the ground which would have made them difficult to fill. Also, I was worried that the extra weight of the fertilizer would have increased soil compaction. My air seeder tank takes the weight of the seed and fertilizer off the drill and is mounted on flotation tires that reduce compaction.

"I use a double hopper drill fill on my truck to fill the caddy. Tractor hydraulics operate two hydraulic motors that drive a pair of augers, allowing me to load seed and fertilizer simultaneously. The caddy holds as much seed as the drill did and allows me to seed 20 to 25 acres between fills. It takes only about 10 minutes to fill both compartments. I don't have to back up a truck and raise the hoist which saves time. Another advantage is that the drill has no disc openers or bearings so there's less maintenance than on a conventional drill.

"I chose the Blanchard air seeder because it has a simple, reliable metering system. The pto-operated blower runs at more consistent rpm's than a hydraulic-driven one and eliminates the possibility of overheating the tractor's hydraulic system.

Bloomquist used steel tubing to build his own extended markers for the drill.

Contact: FARM SHOW Followup, Rudi Bloomquist, RCB Farm, Starkweather, N. Dak. 58377 (ph 701292-4131).

Click here to download page story appeared in.

Click here to read entire issue

Air seeder built from drills HITCHES Hitches 17-1-26 "It works as good as any air seeder on the market. I spent only $8,500 to build it," says Rudi Bloomquist, Starkweather, N. Dak., who converted two 11-ft. Morris hoe drills into a state-of-the-art air seeder by removing the seed boxes and metering drives and mounting a pair of seed-distributing manifolds on the drill frame. A two-compartment Blanchard air seeder caddy delivers seed and fertilizer to the manifolds which then distribute them through tubes to each hoe opener.

One compartment holds 45 bu. of seed and the other holds about 1,200 lbs. of fertilizer. Seed and fertilizer are blown by a pto-driven fan through hoses from the caddy to the manifolds on the trailing drill. Then 1-in. dia. plastic tubes deliver the mixture to pipe shanks that support the drill's hoe openers.

"I've used it for six years and have been pleased with its reliability and simplicity," says Bloomquist. "I've looked at several new air seeders and can't see that they have any advantages over mine. I paid $8,500 for the caddy and another $500 for an extra set of manifolds (which I can also use on a 33-ft. field cultivator to apply granular herbicides). Many of my neighbors paid $40,000 for their conventional 30-ft. air seeders.

"I used the two 11-ft. hoe drills together conventionally for five years. However, I wanted to switch to an air seeder delivery system because I wanted to apply dry fertilizer while seeding. The company offered an add-on, gravity-feed dry fertilizer system for the drill, but it would have cost $100 per foot or $2,200. I would have had to mount the gravity-feed fertilizer boxes 8 1/2 ft. off the ground which would have made them difficult to fill. Also, I was worried that the extra weight of the fertilizer would have increased soil compaction. My air seeder tank takes the weight of the seed and fertilizer off the drill and is mounted on flotation tires that reduce compaction.

"I use a double hopper drill fill on my truck to fill the caddy. Tractor hydraulics operate two hydraulic motors that drive a pair of augers, allowing me to load seed and fertilizer simultaneously. The caddy holds as much seed as the drill did and allows me to seed 20 to 25 acres between fills. It takes only about 10 minutes to fill both compartments. I don't have to back up a truck and raise the hoist which saves time. Another advantage is that the drill has no disc openers or bearings so there's less maintenance than on a conventional drill.

"I chose the Blanchard air seeder because it has a simple, reliable metering system. The pto-operated blower runs at more consistent rpm's than a hydraulic-driven one and eliminates the possibility of overheating the tractor's hydraulic system.

Bloomquist used steel tubing to build his own extended markers for the drill.

Contact: FARM SHOW Followup, Rudi Bloomquist, RCB Farm, Starkweather, N. Dak. 58377 (ph 701292-4131).

To read the rest of this story, download this issue below or click

here to register with your account number.