Compactor For Big Roung Bales

✖  |

"It's the coming thing," predicts Dr. Wesley Buchele, Iowa State University agricultural engineer who, along with undergraduate students he teaches, is exploring the possibility of compacting big round bales to one-third their original size to make them easier to transport both domestically and overseas.

About 20 years ago, Dr. Buchele designed a prototype big baler that sparked one of the fastest-growing new trends in haymaking history. He predicts that compacted big bales will soon enter channels of commerce: "We'll eventually ship compressed giant round bales from the Midwest by barge to Europe, Alaska, Japan, Hawaii and other countries needing alfalfa hay."

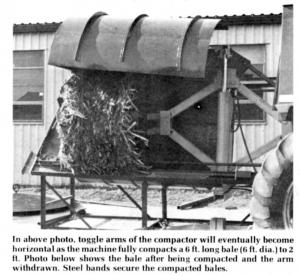

The accompanying photos show a prototype compactor designed and built by Iowa State University students enrolled in a design course taught by Dr. Buchele. It features a double toggle mechanism connected together by two double acting hydraulic cylinders which serve as the driving link to compress bales 6 ft. long and 6 ft. in dia. to only 2 ft, long.

Compacted bales are double strapped with steel bands to prevent them from springing back to their original shape after being compressed. Density of the bales when baled in the field is approximately 6 lbs. per cu. ft. Density after compacting them is about 18 lbs. per cu. ft. which, Dr. Buchele feels, is minimum for economical shipment by various common carriers.

In their project report, the students note that "as density of the bales increases, moisture content must be lower to prevent spoilage. Before bales are compressed, they should be allowed to dry down to 25 or 30% moisture content to prevent spoilage that could occur after compression. For this reason, and because cost of the machine is prohibitive for a single rancher or farmer unless he has a very high volume, the compacting machine need not be portable. We foresee the demand for a single machine for each town or township at a central location. Farmers or ranchers could transport bales to the machine. The compressed bales could then be loaded immediately onto trucks for transport."

Click here to download page story appeared in.

Click here to read entire issue

Compactor For Big Roung Bales HAY & FORAGE HARVESTING Bale Handling (5) 1-6-31 "It's the coming thing," predicts Dr. Wesley Buchele, Iowa State University agricultural engineer who, along with undergraduate students he teaches, is exploring the possibility of compacting big round bales to one-third their original size to make them easier to transport both domestically and overseas.

About 20 years ago, Dr. Buchele designed a prototype big baler that sparked one of the fastest-growing new trends in haymaking history. He predicts that compacted big bales will soon enter channels of commerce: "We'll eventually ship compressed giant round bales from the Midwest by barge to Europe, Alaska, Japan, Hawaii and other countries needing alfalfa hay."

The accompanying photos show a prototype compactor designed and built by Iowa State University students enrolled in a design course taught by Dr. Buchele. It features a double toggle mechanism connected together by two double acting hydraulic cylinders which serve as the driving link to compress bales 6 ft. long and 6 ft. in dia. to only 2 ft, long.

Compacted bales are double strapped with steel bands to prevent them from springing back to their original shape after being compressed. Density of the bales when baled in the field is approximately 6 lbs. per cu. ft. Density after compacting them is about 18 lbs. per cu. ft. which, Dr. Buchele feels, is minimum for economical shipment by various common carriers.

In their project report, the students note that "as density of the bales increases, moisture content must be lower to prevent spoilage. Before bales are compressed, they should be allowed to dry down to 25 or 30% moisture content to prevent spoilage that could occur after compression. For this reason, and because cost of the machine is prohibitive for a single rancher or farmer unless he has a very high volume, the compacting machine need not be portable. We foresee the demand for a single machine for each town or township at a central location. Farmers or ranchers could transport bales to the machine. The compressed bales could then be loaded immediately onto trucks for transport."

To read the rest of this story, download this issue below or click

here to register with your account number.