1994 - Volume #18, Issue #3, Page #02

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Pickup Bale Handler Hauls 3 Bales At A Time

|

|

|

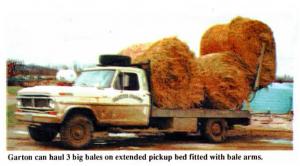

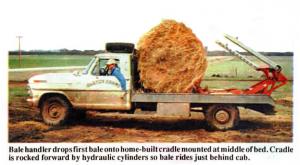

Robert Garton, Moundville, Mo., added 30 in. to the truck's frame between the cab and rear axle, increasing bed length to 10 ft. 9 in. long. A commercial bale handler equipped with a pair of bale squeeze arms mounts at the rear of the bed. It drops the first bale onto a home-built cradle mounted at the middle of the bed. The cradle is rocked forward by hydraulic cylinders so the bale rides just behind the cab. The bale arms then pick up a second bale and place it behind the first one, then they hold the third bale for transport.

"Bales can be unloaded over a fence, placed into feeders, or unrolled with the aid of spinners that slip into the bale squeeze arms," says Garton. "The bed's built close to the ground for a low center of gravity."

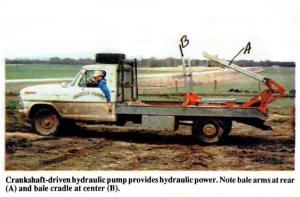

When he extended the pickup frame, Garton built a new 2-piece driveline with a center carrier bearing to reduce vibration. A crankshaft-driven hydraulic pump provides hydraulic power. He used a combine hydraulic pump and an air conditioner belt drive (so he can turn the pump on and off electrically from inside the cab), using the air compressor mounting brackets. There are open grate-type running boards along the cab and the front part of the bed on each side and a tool box mounts under the bed. Contact: FARM SHOW Followup, Robert Garton, Rt. 1, Moundville, Mo. 64771 (ph 417 922-3265).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.