New Mill Rolls Grain Without Dust, Fines

✖  |

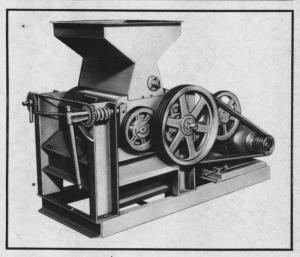

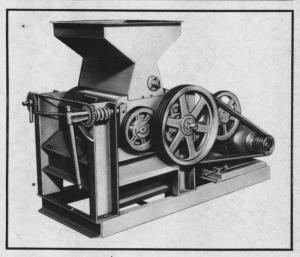

"We developed it to meet the needs of pork producers," says Ramsey Davis, president of H.C. Davis Sons Mfg. Co., Bonner Springs, Kan., manufacturer of the new Krimper-Kracker roller mill which processes grain "a lot cheaper than a hammer mill ù and with virtually no dust or fines."

"Roller mills have always required far less power than hammer mills, but their finished product was too coarse for hogs in general and especially baby pigs. We've solved this problem with our new Krimper-Kracker," explains Davis. "By operating one roll faster than the other, a shearing and tearing action is achieved that results in a granular grind with very little objectionable dust and fines. Particle size of the finished product is determined by speed and corrugation of the rolls. Regardless of the corrugation or differential speed used, product uniformity remains constant ù with dust and fines practically eliminated," Davis points out.

He notes that roller mills require only about one-fourth the power needed to operate hammer mills: "Roller mills require an average of 17,300 btu's of electrical energy per ton processed, compared to about 73,400 btu's per ton for hammer mills. Using this example, the cost to roll one ton of grain would be right at 25 cents, whereas for a hammer mill grinder it would be $1.07, based on electricity at 5 cents per KWH."

The new Krimper-Kracker is available in three models ranging from 50 to 400 bu. of corn, milo, wheat, barley or oats per hour. With rollers measuring 10 in. in dia. by 20 in. long, for example, capacity is 200 bu./hr. It retails for right at $3,000 and requires a 10 hp motor. The largest "12 by 30" model processess 400 bu./hr., requires a 30 hp motor and retails for $6,700. The "10 by 10" processes 50 bu./hr., requires a 10 hp motor, and retails for $1,800.

For more details, contact: FARM SHOW Followup, H.C. Davis Sons Mfg. Co., P.O. Box 395, Bonner Springs, Kan. 66012 (ph 913 422-3000).

Click here to download page story appeared in.

Click here to read entire issue

New Mill Rolls Grain Without Dust,Fines LIVESTOCK Feeding Equipment 7-4-32 "We developed it to meet the needs of pork producers," says Ramsey Davis, president of H.C. Davis Sons Mfg. Co., Bonner Springs, Kan., manufacturer of the new Krimper-Kracker roller mill which processes grain "a lot cheaper than a hammer mill ù and with virtually no dust or fines."

"Roller mills have always required far less power than hammer mills, but their finished product was too coarse for hogs in general and especially baby pigs. We've solved this problem with our new Krimper-Kracker," explains Davis. "By operating one roll faster than the other, a shearing and tearing action is achieved that results in a granular grind with very little objectionable dust and fines. Particle size of the finished product is determined by speed and corrugation of the rolls. Regardless of the corrugation or differential speed used, product uniformity remains constant ù with dust and fines practically eliminated," Davis points out.

He notes that roller mills require only about one-fourth the power needed to operate hammer mills: "Roller mills require an average of 17,300 btu's of electrical energy per ton processed, compared to about 73,400 btu's per ton for hammer mills. Using this example, the cost to roll one ton of grain would be right at 25 cents, whereas for a hammer mill grinder it would be $1.07, based on electricity at 5 cents per KWH."

The new Krimper-Kracker is available in three models ranging from 50 to 400 bu. of corn, milo, wheat, barley or oats per hour. With rollers measuring 10 in. in dia. by 20 in. long, for example, capacity is 200 bu./hr. It retails for right at $3,000 and requires a 10 hp motor. The largest "12 by 30" model processess 400 bu./hr., requires a 30 hp motor and retails for $6,700. The "10 by 10" processes 50 bu./hr., requires a 10 hp motor, and retails for $1,800.

For more details, contact: FARM SHOW Followup, H.C. Davis Sons Mfg. Co., P.O. Box 395, Bonner Springs, Kan. 66012 (ph 913 422-3000).

To read the rest of this story, download this issue below or click

here to register with your account number.